Decarbonise Today. Unlock the Future of Hydrogen

For decades, fossil fuels continue to dominate energy production. The emissions generated by its combustion significantly contribute to climate change and global rising temperatures. Collective action across governments and industries is key to achieve net-zero carbon emission targets, address societal impact and climate risks.

Stepping up to the urgency for a just energy transition that reduces greenhouse gas emission and reliance on fossil fuels, ST Engineering Energy Solutions brings to the table the next frontier in hydrogen technologies. We can support you end-to-end in implementing hydrogen projects – from planning to commissioning – benefitting from our alkaline electrolysis technology – modular, reliable and cost-efficient.

The Game-Changer in Hydrogen Production

A future without fossil fuels requires a fundamental transformation in industry, mobility, and energy supply. Hydrogen and hydrogen-based fuels bridge the gap where electricity cannot fully replace fossil fuels. Together with our partners, we provide tailored solutions for decarbonisation with hydrogen.

Safe and reliable operation is essential for the success of your project. That is why we have engineered HubGen from ground up, incorporating decades of learning experience in the sector. And that is what sets us apart.

With one of the most experienced teams in the industry, we drive technological advancements for you. Our design philosophies take advantage of standardisation principles and industrial best practices to ensure smooth operation for both the electrolyser and your existing processes, saving you time and costs.

We know how to harness the power of data to optimise system operations and have built intelligent monitoring algorithms to maintain maximum system uptime. Protected by robust cyber security systems, we empower our customers to keep operations reliable and stable.

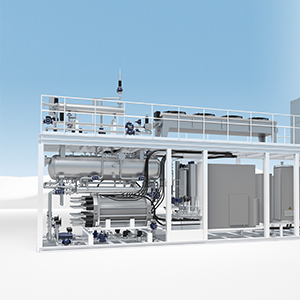

HubGen 1000:

Ready for dynamic operation, designed for lowest LCOH

Efficient

High system efficiency of 57kWh/kg of H2 and high-pressure output of 30 bar, reducing significant total operating cost (TCO)

Plug & produce

Modular, compact system for rapid project execution – maximum standardisation for an accelerated approval process

Safe & stable

The system is designed for maximum reliability, using only proven components. CE ensure that the product meets the relevant EU directives and standards

Smart & secure

Data-driven, intelligent monitoring for highly efficient system operation – protected by robust cyber security systems

Availability

Standardised design based on existing supply chains. Custom-engineered power electronics

All-in-One & scalable

1-MW of power in minimal space – no additional buildings or support systems required – easily accessible and simple to maintain

Your Trusted Partner for Electrolyser Solutions

We take a holistic approach to project execution that includes comprehensive customer support

01.

Technical

Support

We guide you through the technical feasibility assessment, integration with your systems, and hands-on training for the optimal operation of your electrolyser.

02.

End-to-End

Implementation

From concept to real-world operation: We are your trusted partner for the delivery and implementation of electrolysers.

03.

Simple Digitalisation

With us, you will operate your electrolyser using intelligent AI solutions and remote monitoring for maximum uptime. All secured by robust cyber security systems.

04.

Smart Maintenance

Local expertise meets remote solutions, ensuring your operations run as reliably and smoothly as a Swiss watch.

01.

Technical

Support

We guide you through the technical feasibility assessment, integration into your systems, and hands-on training for the optimal operation of your electrolyzer.

02.

End-to-End Implementation

From concept to real-world operation: We are your trusted partner for the delivery and implementation of electrolyzers.

03.

Simple Digitalization

With us, you will operate your electrolyzer using intelligent AI solutions and remote monitoring for maximum uptime. All secured by robust cyber security systems.

04.

Smart Maintenance

Local expertise meets remote solutions, ensuring your operations run as reliably and smoothly as a Swiss watch.

Questions? We Have the Answers!

Even more:

it is designed to handle fluctuating energy supply.

Even more:

it is designed to handle fluctuating energy supply.

Hydrogen, a key technology

for successful energy transition

Long-Term Energy Storage

Hydrogen is an ideal storage solution for excess energy. It allows you to store renewable energy efficiently, reducing fluctuations and ensuring stable power supply. This is particularly important as the world increasingly relies on intermittent renewable energy sources, which require effective storage solutions to maintain grid stability. At the end of the energy transition, hydrogen electrolysis from surplus electricity needs to produce approximately 50 TWh of electrical power in Germany per year.

Make use of surplus electricity today. Produce hydrogen at negative energy prices and save money.

.

Hard-to-Abate Industry

Steel, chemicals, cement – heavy industries need high energy input mainly for high heat processes. These are difficult to electrify or decarbonise using conventional renewable energy sources. Hydrogen can serve as a low-carbon fuel or feedstock in these sectors, providing a pathway to meet stringent emission reduction targets.

To accelerate decarbonisation, multiple regulations are in place to meet the Paris Climate Agreement: governments are continuously increasing CO2 taxes, introducing a quota for the use of clean hydrogen up to 42% in 20301, and stringent requirements for reducing emissions arising from the supply chain2. These regulations also affect your company.

Switch to decentralised hydrogen production now and benefit from extensive publicly available subsidy schemes.

[1] RED III – Renewable Energy Directive [2] European Supply Chain Act

Transport and Mobility

Whether it’s the logistics, shipping, or aviation industry, the future of transportation must drastically reduce reliance on fossil fuels – and in the long term, almost entirely eliminate them.

In the U.S., fuel cell propulsion systems are already widely used in logistics, in equipment handling such as forklifts and baggage tractors at airports.

Hydrogen offers significant advantages over battery-electric drives. Long ranges and short refuelling times enhance vehicle availability.

Save time and cost. Produce your own hydrogen on-site with HubGen 1000.

Stay tuned!

ST Engineering Energy Solutions is committed to an emission-free future. Discover our portfolio and the exciting advancements ahead.

2025

HubGen 1000: plug-and-produce fast, simple, reliable 1MW capacity system

01

02

2026

Integrated energy

management solutions

2027

Scaling up to

industrial plant level

03

About ST Engineering Energy Solutions

ST Engineering Energy Solutions GmbH is shaping technological leadership in the global hydrogen economy. Located in Germany, we pride ourselves by understanding the various pain points across industries and deliver what our partners and customers truly need in their energy transition.

As a wholly owned subsidiary of global technology, defence and engineering group, ST Engineering, our international expertise across diverse disciplines enables us to tailor and broaden solutions for a sustainable and energy secure world.

With a rich heritage of more than 50 years, ST Engineering harnesses technology and innovation to solve real-world problems. Headquartered in Singapore, the Group has operations spanning Asia, Europe, the Middle East and the U.S., serving customers in over 100 countries.

More about ST Engineering: www.stengg.com